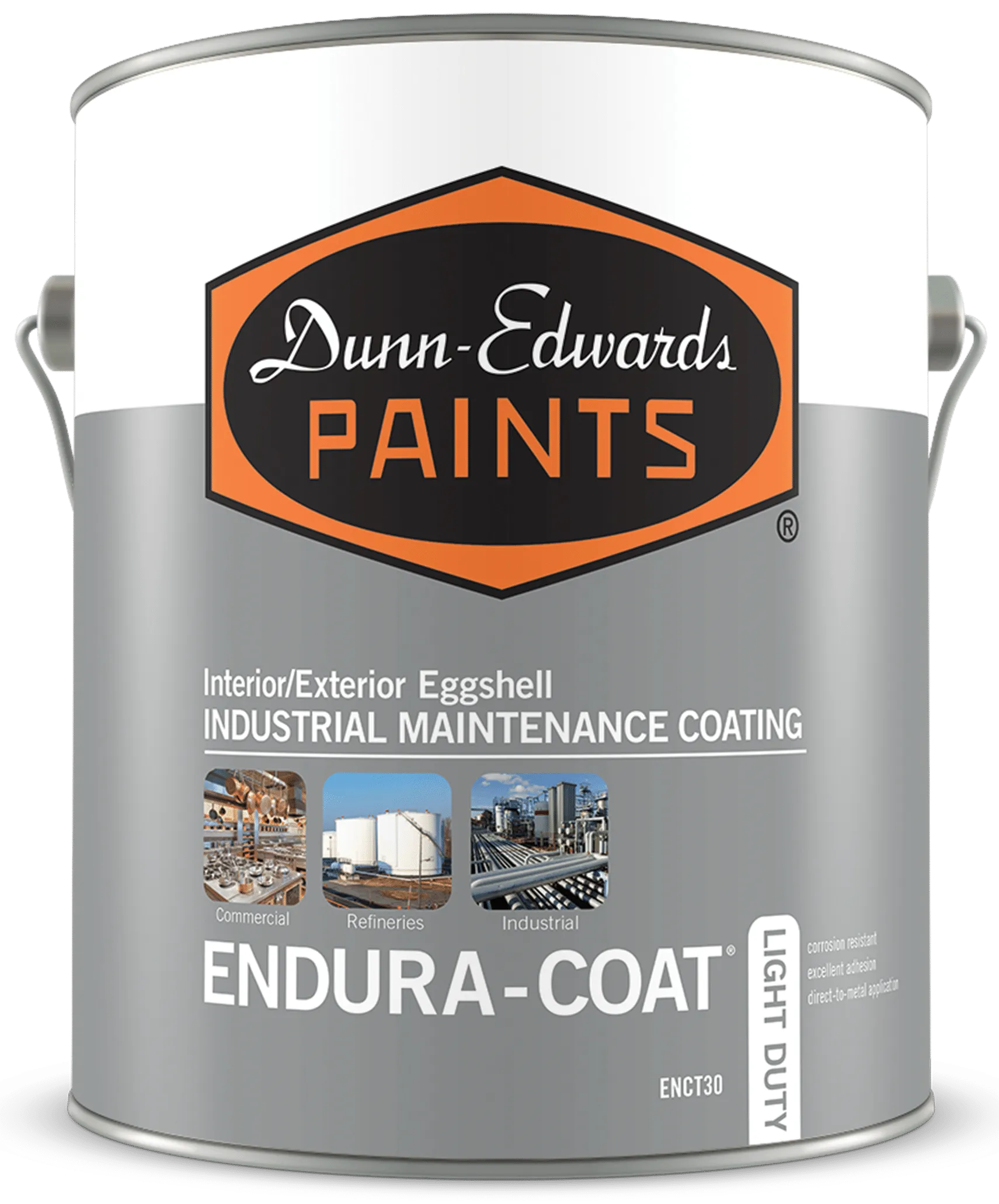

ENDURA-COAT®

Interior/Exterior Industrial Maintenance Coating

ENDURA-COAT® is a high performance, interior/exterior, low VOC, direct to metal, water-based acrylic Industrial Maintenance Coating with excellent corrosion resistance and direct-to-metal properties. It can be used on properly prepared and primed metal, wood, masonry, plaster or drywall. ENDURA-COAT is available in eggshell, semi-gloss and gloss finishes.

Excellent corrosion resistance and adhesion

Superior hardness, durability and gloss retention

Direct-to-metal (DTM) application

Case StudiesSEE THE ENDURA-COAT® DIFFERENCE FOR YOURSELF

RECOMMENDED PRIMERS

Drywall

Surface

Recommended Primer

Masonry

Surface

Recommended Primer

Plaster

Stucco

Tilt-Up Concrete

Poured-In-Place Brick

Concrete Block

Smooth Trowel

Wood

Surface

Recommended Primer

Trim, sash

Synthetic Wood

Surface

Recommended Primer

Masonite, Hardboard, MDO siding

Metal

Surface

Recommended Primer

Find a Store

Dunn-Edwards products are sold in 149 company stores and 90 dealers across Arizona, California, Nevada, New Mexico Kentucky, Montana, Oregon, Texas, Utah and Wyoming.

How to videos

Our library of how-to videos addresses an array of painting topics, including color selection, prep, application and aftercare. Check it out - you never know what great tips you might find!