ENDURALASTIC® 10

Exterior elastomeric wall coating

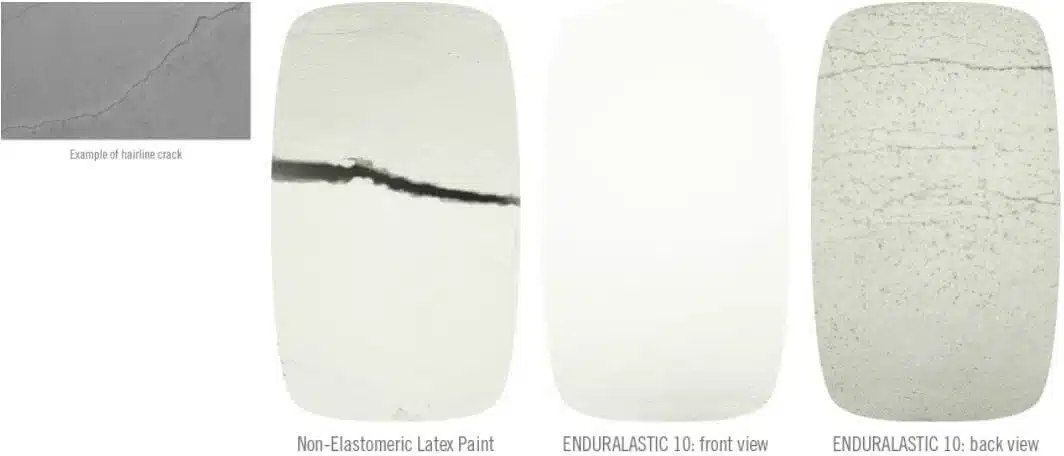

ENDURALASTIC® 10 is an ultra-premium specialty 100% acrylic elastomeric wall coating designed for use on exterior surfaces. ENDURALASTIC 10 has exceptional flexibility, chalking and binder degradation resistance, and provides outstanding waterproofing protection against wind-driven rain by bridging hairline cracks. ENDURALASTIC 10 also provides excellent adhesion and outstanding alkali and efflorescence resistance on properly prepared masonry.

Superior elasticity and elongation

Excellent crack bridging properties

Waterproofs against wind-driven rain

Great dirt pick-up resistance

Case StudiesApplications

SEE THE ENDURALASTIC™ DIFFERENCE FOR YOURSELF

RECOMMENDED PRIMERS

Masonry

Surface

Recommended Primer

Plaster, Stucco (new), Stucco (repaint), Tilt-up Concrete, Poured-in-place, Brick, Smooth Trowel

Concrete Block

Find a Store

Dunn-Edwards products are sold in 149 company stores and 90 dealers across Arizona, California, Nevada, New Mexico Kentucky, Montana, Oregon, Texas, Utah and Wyoming.

How to videos

Our library of how-to videos addresses an array of painting topics, including color selection, prep, application and aftercare. Check it out - you never know what great tips you might find!