Principles

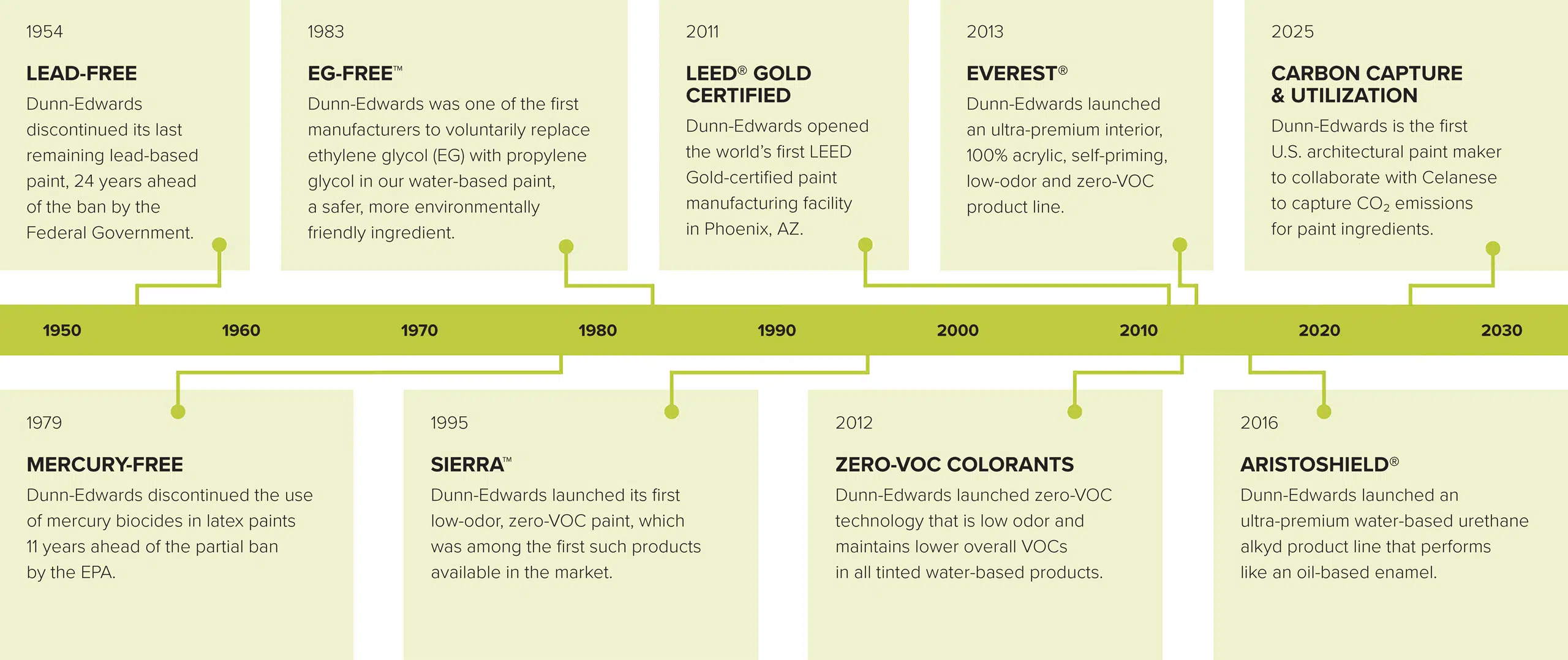

Dunn-Edwards is firmly committed to the over-arching green principle of eco-efficiency. We define “eco-efficiency” as the ability to satisfy human needs in ways that minimize adverse impacts on energy and material resources, environmental quality and human health and safety. For us, eco-efficiency means: “do more good,” by optimizing the performance of our paint products, and “do less harm,” by reducing or avoiding the use of harmful ingredients. Other green principles flow from the principle of eco-efficiency: resource conservation, energy efficiency, waste minimization, recycling, emissions reduction, health and safety protection, and social responsibility.

What makes Dunn-Edwards paint greener?

It’s not only the performance we put into our paint, but also what we leave out. Dunn-Edwards constantly seeks to reduce or avoid the use of potentially harmful ingredients. Consequently, our paint formulations do not include – among other things – asbestos, benzene, cadmium and chromium pigments, chlorinated solvents, dioxin, ethylene glycol, formaldehyde, lead, mercury, methylene chloride, or phthalates.

Practices

Dunn-Edwards is absolutely committed to full compliance with all applicable environmental, health and safety laws and regulations. This commitment extends companywide, from senior management through staff in all departments. Beyond compliance, Dunn-Edwards has a long history of proactively doing more than required, often taking action before any requirement exists.

Find participating recycling stores

Dunn-Edwards has partnered with PaintCare™, a non-profit that collects, recycles and safely disposes of open paint cans. If you’re a California resident, enter your ZIP code to find a recycling location near you.

To view national PaintCare drop-off locations or learn more information, visit paintcare.org

Carbon Capture and Utilization (CCU) Technology with Celanese

In collaboration with Celanese Corporation, Dunn-Edwards is the pioneer of Carbon Capture and Utilization (CCU) technology in the U.S. architectural coatings industry. This innovative process captures industrial CO2 emissions and transforms them into key ingredients for our paints. The resulting paint products offer a lower carbon footprint and contribute to a more eco-efficient built environment.

PEOPLE

Dunn-Edwards respects the inherent worth of each individual, and we strive to conduct all our business with the highest sense of ethics, integrity and responsibility.

PAINTING GREEN ARTICLES

“Sustainability” has long been the watchword of the green building movement. There are times, however, when the concept of sustainability can be difficult to grasp or put to use in practical, clearly meaningful ways.

LEARN MORE